How a Cardboard Box Factory Ensures Quality and Sustainability

A cardboard box factory plays a crucial role in the packaging industry, supplying durable and eco-friendly packaging solutions for businesses worldwide. From custom packaging to large-scale shipping solutions, these factories are at the forefront of innovation. In this blog, we will explore how a cardboard box factory operates, the benefits of using cardboard packaging, and key factors to consider when choosing a reliable manufacturer.

Why Choose Cardboard Packaging?

Cardboard boxes Factory are a popular packaging choice due to their versatility, durability, and eco-friendliness. Here’s why businesses prefer them:-Sustainable Material: Made from recycled paper and biodegradable materials.

-Lightweight and Strong: Provides excellent protection while being easy to handle.

-Customizable: Can be tailored to different sizes, shapes, and branding needs.

-Cost-Effective: Affordable packaging solution with minimal environmental impact.

How a Cardboard Box Factory Operates

1. Raw Material Sourcing-Factories use high-quality recycled paper and sustainable materials.

-Advanced processes ensure minimal waste and energy efficiency.

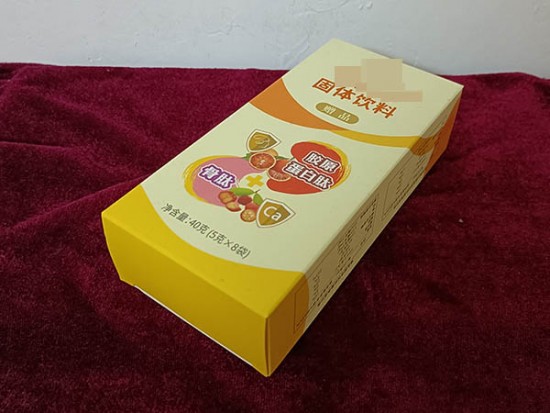

2. Design and Customization

-Businesses can choose from a variety of box types, including:

-Corrugated boxes for heavy-duty shipping.

-Folding cartons for retail packaging.

-Die-cut boxes for unique branding needs.

-Digital and offset printing options for logos and branding elements.

3. Manufacturing Process

-Cutting and shaping the cardboard using precision machinery.

-Applying protective coatings for enhanced durability.

-Assembling and testing for strength and quality assurance.

4. Quality Control and Distribution

-Each batch undergoes rigorous testing for durability and load-bearing capacity.

-Boxes are stored and distributed based on client requirements.

-Logistics solutions ensure timely delivery to businesses worldwide.

Choosing the Right Cardboard Box Factory

1. Experience and Reputation-Look for manufacturers with a proven track record in the industry.

-Read customer reviews and check for certifications.

2. Customization Capabilities

-Ensure the factory offers a range of design and printing options.

-Inquire about prototype samples before bulk production.

3. Sustainability Practices

-Choose factories that prioritize eco-friendly production processes.

-Verify their use of recycled materials and energy-efficient methods.

4. Pricing and Lead Times

-Compare pricing among manufacturers to get the best value.

-Confirm production timelines to align with business needs.

Conclusion

A reliable cardboard box factory provides businesses with high-quality, sustainable, and customizable packaging solutions. Whether you need sturdy shipping boxes or branded retail packaging, choosing the right factory ensures efficiency and cost-effectiveness. By focusing on quality, sustainability, and customer needs, these factories help businesses meet their packaging demands while minimizing environmental impact.